Customers

Scrapman weighing systems have been in use 24/7 in steelworks around the globe in some of the most hostile conditions possible and in climates ranging from Saudi Arabia, through Australia to Sweden and Latvia. Some of our steelworks clients are listed below;

- Outokumpu - Sheffield UK

- Forgemasters - Sheffield UK

- National Steel & Iron Factory - Dammam, Saudi Arabia

- Tata Steel (UK) - Rotherham UK

- Tata Steel (UK) - Scunthorpe UK

- CMC (Croatia) - Sisak, Croatia

- Onesteel - Newcastle, Australia

- Metalurgs - Jelgavas, Latvia

- Ovako - Smedgebacken,Sweden

- Tube City (ThyssenKrupp) - Calvert, Alabama, USA

- Tube City (Hoeganaes) - Gallatin, Tennessee, USA

Our involvement with scrap weighing systems dates back to 1996 when we were approached by Slag Reduction (now Harsco) to design a complex IT system for weighing scrap steel in baskets, on trailers and processing HEAT's (Hot Metal Orders or Recipes) right through from the scrapyard to the melt shop. This first system went live in August 1997 and has been running 24/7 ever since. It is highly probable that we were the first company to create such a system; if we weren't the first then we were certainly amongst the first and whilst we're primarily a systems house, we've gained a lot of experience of the steel industry during our association.

The first system installed at Avesta Sheffield (now Outokumpu) included the following plant;

- Six-off - 180T Trailers

- Three-off - Tractor Units

- Three-off - Grab Cranes

- Two-off - Caterpillar Front Loaders

1, Tractor, Trailer and Scrap Basket. 2, Scrap Basket being loaded

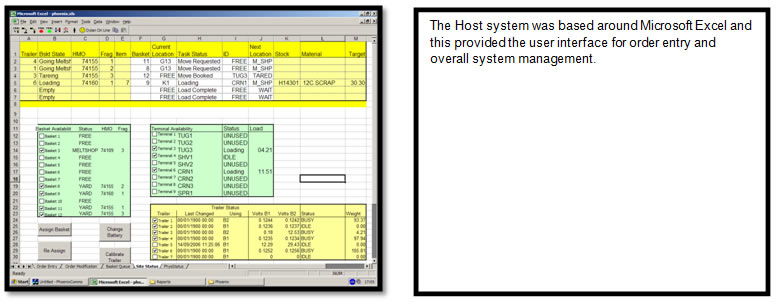

The host computer with its application software was linked to the steelworks database and used for receiving HEAT information (Scrap Material Description, Stock Codes, Target Loads) and sending back actual Stock usage reports.

The IT part of the system involved small computers in the trailers for weighing scrap in the basket, touch-screen computers in Tractor, Crane and Front-loader cabs and a host system resident on a PC. All the mobile plant was linked via radio-modem and the host computer with its application software was linked to the steelworks database; this was the link for receiving HEAT's and sending back Stock-Used reports.

System Overview